Had Willy Wonka had been fascinated by industrial ecology instead of cocoa beans, his factory may have looked something like The Plant, Chicago’s first entirely self-sustaining "vertical farm."

The Plant occupies a former meatpacking plant and slaughterhouse in the Union Stock Yards, transforming a huge brick building that once specialized in bringing red meat to the masses into a green space all about urban farming without waste. The interior looks like something straight out of a scientific-environmental fantasy.

Tenants include aquaponic farms (think vegetables on water beds flourishing under colored UV lights), a tilapia fish farm, beer and Kombucha tea breweries, a mushroom garden, and a host of independent bakers and caterers that will work together in a communal kitchen space. Future plans include living walls and rooftop gardens.

But the most ambitious part of the building is its focus on producing "net-zero waste" in its 93,500-square-foot space. Spent grains from the beer brewery will feed the tilapia. The waste produced by the fish will feed the mushroom garden or be converted nitrates to feed the hydroponic plants. Those plants will clean the water through natural processes and be cycled back into the fish tanks. Taken together, the system will make the building completely self-sustainable. With the help of a few machines, including an anaerobic digester (similar to a waste-eating mechanical "stomach" that produces biogas) and a combined heat and power system, the building hopes to go off the grid within the next four years.

“Industrial ecology—the concept of using other people’s waste as input—is fascinating. In nature, there’s no waste, but there is so much waste in human consumption and development,” says Melanie Hoekstra, The Plant's director of operations. “This is an obvious problem that we can resolve with a building that can do so many things. It’s not a perfect system, but it’s really close.”

The building, which was purchased in July 2010, is currently undergoing renovations by a team of volunteers. The Plant plans to have five tenant spaces ready for lease by the end of this year and the renewable energy system running by next June. The building will be fully functional in 2016, creating 125 jobs in the neighborhood diverting more than 10,000 tons of food waste from landfills each year.

"You can do this in any building—any old manufacturing building as long as there’s space to take heat," Hoekstra says. "The most important thing is using the resources that you already have around you."

Photos courtesy of The Plant and Rachel Swenie

[youtube]https://www.youtube.com/watch?v=zMBxJTQqnRI

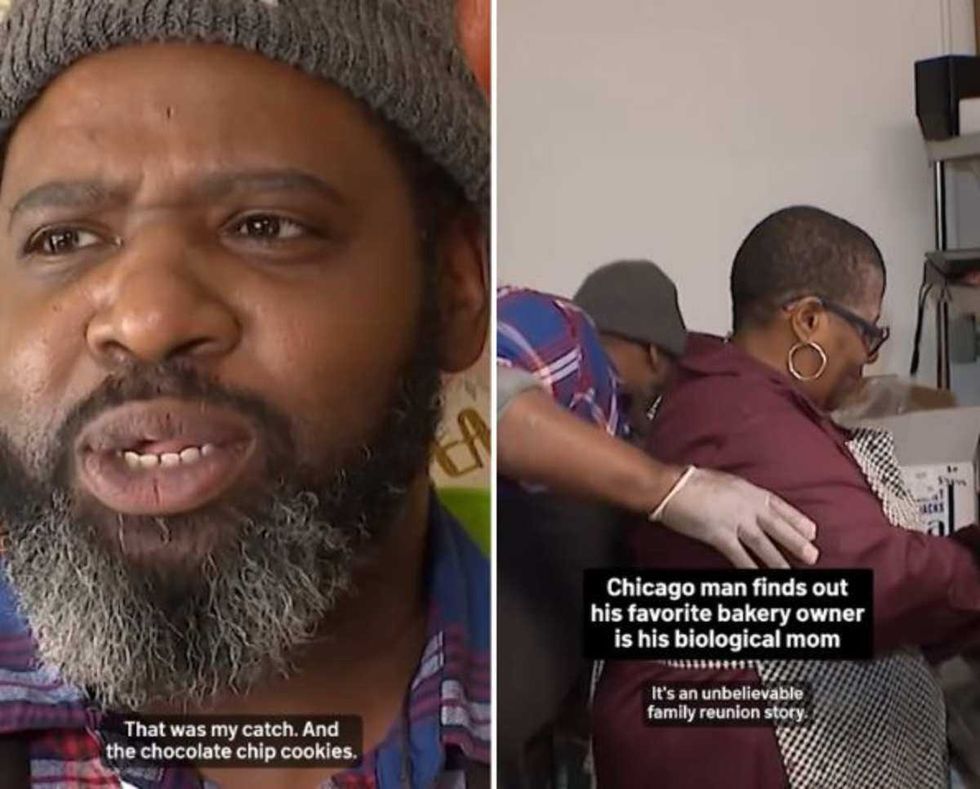

Screenshots of the man talking to the camera and with his momTikTok |

Screenshots of the man talking to the camera and with his momTikTok |  Screenshots of the bakery Image Source: TikTok |

Screenshots of the bakery Image Source: TikTok |

A woman hands out food to a homeless personCanva

A woman hands out food to a homeless personCanva A female artist in her studioCanva

A female artist in her studioCanva A woman smiling in front of her computerCanva

A woman smiling in front of her computerCanva  A woman holds a cup of coffee while looking outside her windowCanva

A woman holds a cup of coffee while looking outside her windowCanva  A woman flexes her bicepCanva

A woman flexes her bicepCanva  A woman cooking in her kitchenCanva

A woman cooking in her kitchenCanva  Two women console each otherCanva

Two women console each otherCanva  Two women talking to each otherCanva

Two women talking to each otherCanva  Two people having a lively conversationCanva

Two people having a lively conversationCanva  Two women embrace in a hugCanva

Two women embrace in a hugCanva

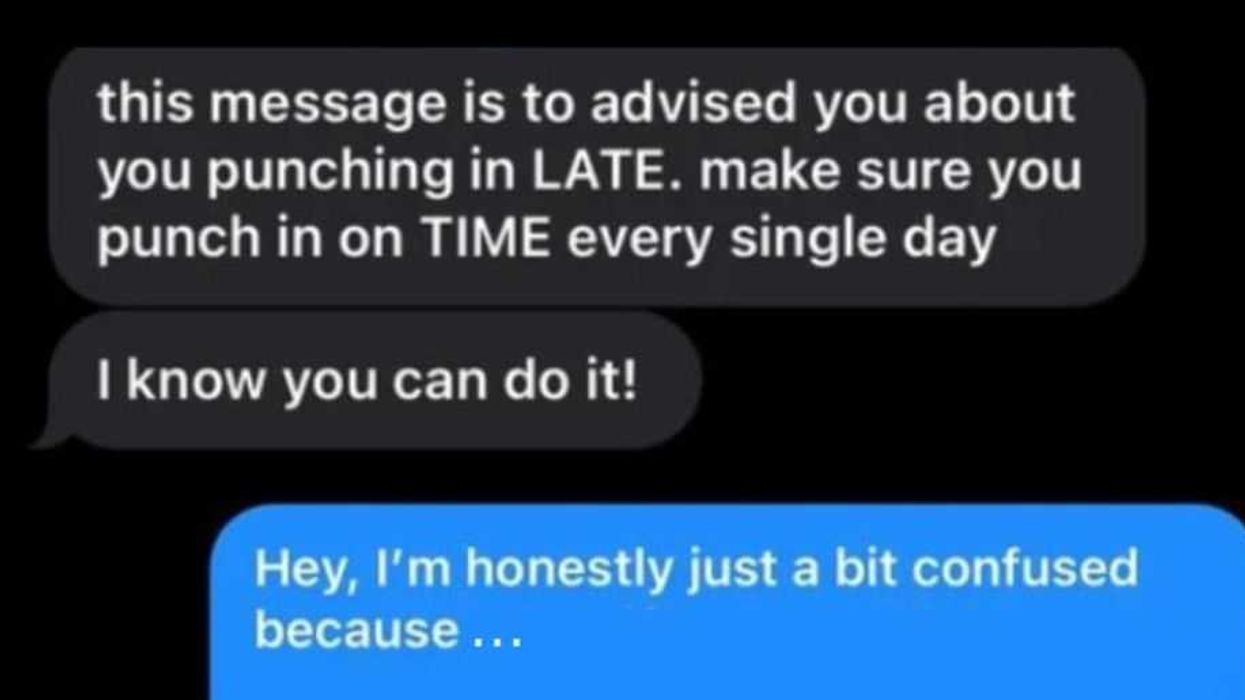

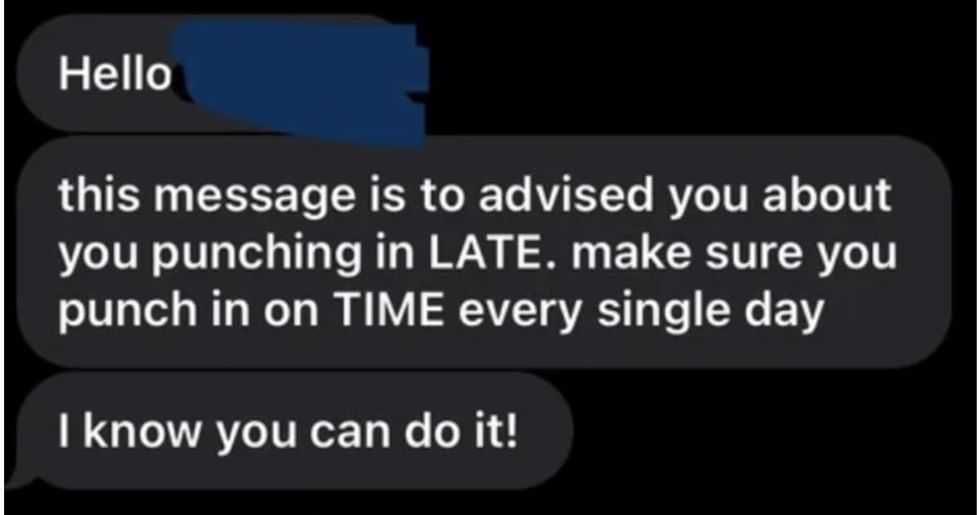

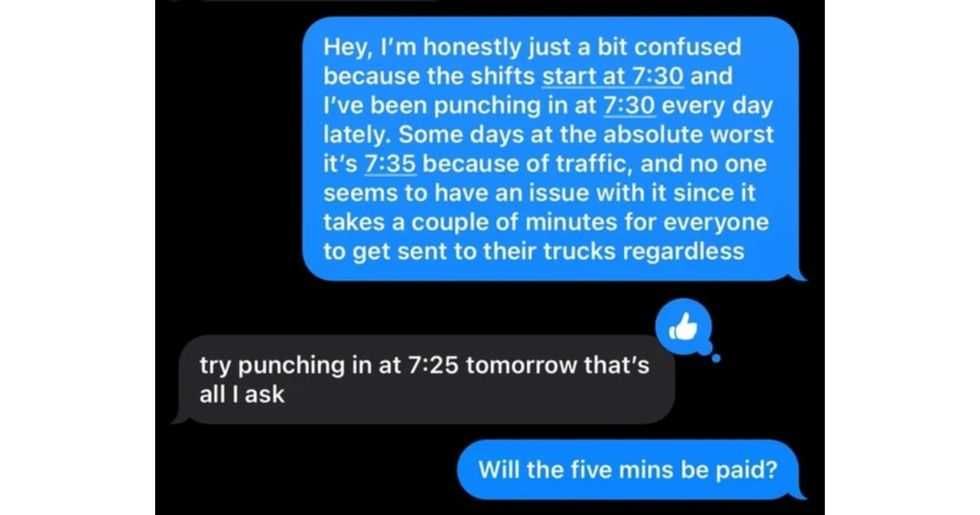

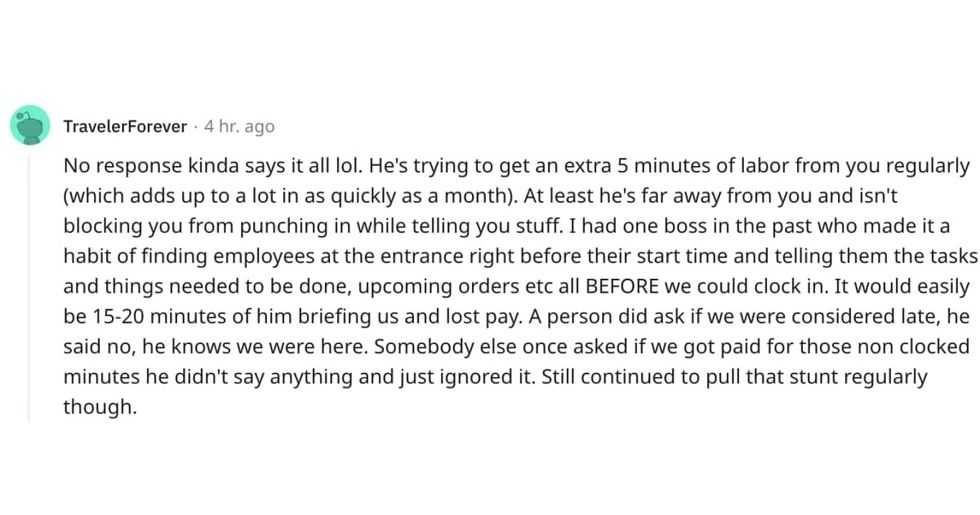

A reddit commentReddit |

A reddit commentReddit |  A Reddit commentReddit |

A Reddit commentReddit |  A Reddit commentReddit |

A Reddit commentReddit |  Stressed-out employee stares at their computerCanva

Stressed-out employee stares at their computerCanva

Who knows what adventures the bottle had before being discovered.

Who knows what adventures the bottle had before being discovered.

Gif of young girl looking at someone suspiciously via

Gif of young girl looking at someone suspiciously via

A bartender makes a drinkCanva

A bartender makes a drinkCanva