If it wasn’t for the Dodge Ram pickup truck, it’s unlikely that Matt Tyler, the CEO of Vickers Engineering in New Troy, Mich., would have purchased the company’s first robot.

First, it was expensive—the robot alone cost more than $50,000 on eBay, plus another $150,000 to program it and train workers to use it. Second, the general sentiment at Vickers was that bringing in a robot meant putting humans out of work.

Vickers doesn’t manufacture things, exactly. It creates parts of things, like brackets, sprockets, and pistons. Instead of an assembly line, its factory is organized into cells which are each operated by one or two workers. An operator in the cell assigned to the 25-pound Ram piece would have to lift the part, bend over to put it into the machine that would stamp it into shape, pull it back out again, and load it onto a pallet—over and over again for eight hours a day.

Nobody wanted to work that cell. So, Tyler reasoned, nobody had grounds to complain if he brought in a robot to do the job.

Even so, Tyler was scared. “I made the assumption that robots were more complicated than they are and that they would be more difficult to maintain,” he says. “I was scared people would be intimidated by seeing the robot in the building.”

He was wrong on all three counts. A clean-cut man in his early 40s, Tyler has been the president and CEO of Vickers for the last 12 years. He now preaches the gospel of robotics with the zeal of a convert.

[quote position="full" is_quote="true"]The questions to ask are: Who controls the machinery and for what purpose?[/quote]

That first robot, it turns out, proved to be a tireless worker that required little more than weekly maintenance. Once the machine came onboard, human workers were no longer required to repeatedly lift 25-pound pieces of metal for entire shifts. They welcomed the opportunity to operate the automated cell as programmers, a job in which they would earn nearly double what they had as manual laborers.

“We solved a need as opposed to a want,” Tyler says. “No one wanted that cell. The recognition of how we transformed that position to one based on technology as opposed to manual labor opened people’s eyes, especially when they saw the wage scale. They started saying, ‘How can I be trained to do that?’”

Seven years later, Vickers has 11 robots working on the factory floor, with three more on the way. Each robot requires three operators: an engineer, a quality technician, and someone in shipping and receiving. While the 160-employee company has hired around 15 new human workers in the past two years, most of the new jobs created by the machines have gone to former cell laborers. There have been no worker protests or, according to Tyler, any complaints at all.

***

I paid a visit to Vickers on a sunny afternoon in June. Located in the middle of southwest Michigan farm country, it is a sprawling factory with a front façade resembling a brick castle. Inside, its cells line a center aisle that stretches the length of the facility. Each cell contains a unique robot built for different metalworking tasks. Some also hold small conveyer belts. The machines work behind protective grilles while humans adjust their movements via nearby computers. Everyone is in constant motion, even the programmers whose main job is to control the robots.

In one cell, a human operator loads a tray full of metal pieces, each about the size of a pair of outspread hands. A robot then picks them up and sets them into a large, taupe-colored, box-shaped machine that molds the pieces into parts. As the robot pulls each part out, it shoots a puff of air at each one to dust off the sharp edges, and then holds it up to a camera. If the part doesn’t match specifications, the robot tosses it into a reject bin. The entire cycle happens in a flash.

The robots at Vickers are not much to look at. They are tall and yellow and bolted into the floor. They were modeled on the human arm—the bottom of each one pivots like a shoulder, with the middle joint swinging back and forth. The top twists like a wrist, and the component at the end grabs like a hand. No blinking eyes, no “speaking” through beeps or clicks. These robots were made to work.

Almost all mass-market automotive paint jobs are now done by robots. So is the spot welding of those cars, the packaging of Hot Pockets, the slicing of the top of machine-made “artisan” baguettes, and tasks across dozens of other industries.

A human could perform these functions, but, unlike a human, a robot doesn’t get tired. It doesn’t slip and fall. Its back doesn’t ache. It doesn’t develop arthritis. It doesn’t even need to clock out after an eight-hour shift. When it finishes a job, it can be reprogrammed to do another one.

Yet the robot is just another tool, albeit a big, expensive one. At Vickers, humans treat it as such. Dick Handlin, the facility’s operations manager, thinks workers will eventually nickname the machines, the way people name their cars. But for now, Vickers employees simply refer to each one by number.

***

“Robots are another potential threat to a sense of security in the working world,” says Leon Fink, a labor historian who teaches at the University of Illinois-Chicago. “We’re in a period of stagnant growth and sticky unemployment with a labor surplus. The idea that more robotics is going to somehow increase the number of jobs seems very far-fetched to me.”

Automated technology has invaded American factories over the last decade, but labor remains one of manufacturing’s primary costs. Fink’s concern is that as the price of technology continues to decline and the size of the labor force continues to increase, the former will marginalize the latter. Tobias Higbie, a professor of labor history at UCLA, echoes this apprehension.

“Managers always say that technology creates jobs,” Higbie says. “This may be true in a narrow sense, but it also displaces jobs and, in the aggregate, there has been more displacement than creation of late. So the questions to ask are: Who controls the machinery and for what purpose?”

As long as industrial automation has been around, Higbie continues, big business has fought to convince the public to cozy up to the idea that technology benefits everyone.

In response to criticism that increased mechanization was leading to widespread unemployment during the 1920s and 30s, electric manufacturing giant Westinghouse crafted a PR campaign for the 1939 New York World’s Fair starring Elektro, a seven-foot-tall Tin Man-like humanoid that blew up balloons and smoked cigarettes, and Sparko, his barking steel canine best friend. The attempt to paint a friendlier picture of robots didn’t quite work. Even in the 1940s, a time of increased manufacturing production boosted by World War II, the leaders of the United Auto Workers union remained convinced that machines were taking jobs from their workers.

In 2012, 26,269 robots went to work in North America. The International Federation of Robots predicts that number will rise to over 31,000 by 2016. Last year’s report on “disruptive technologies” by the McKinsey Global Institute estimated that robots will, by 2025, cost about half as much as they do now, occupy between 15 and 25 percent of jobs currently being performed by humans, and save manufacturers anywhere from $600 billion to $1.2 trillion per year.

According to Mike Cicco, the general manager of distribution for FANUC America Corporation, the largest North American distributor of industrial robots, this is great news. FANUC has been promoting Vickers as a model for the shift from manual to automated labor.

Cicco believes increased efficiency and productivity brings manufacturing work back to America, reviving job opportunities that had previously moved overseas. American manufacturers added 178,000 jobs over the last 12 months, bringing total manufacturing employment to its highest level since 2009. And after almost 15 years of decline, the total number of American factories is experiencing its longest period of stability since 1998.

“What robots are doing don’t make enjoyable careers for people,” Cicco says. “They’re taking the place of the jobs that are so mindless and repetitive or dangerous, or done in an environment that’s dangerous to be in, like an automotive paint shop. You have to put on so much gear to paint, so you don’t get cancer. A job like that requires automation.”

Operating a robot, though, is a job that requires skill and intelligence, but not necessarily a college education. You don’t have to be a young person to do it, and you don’t have to be particularly strong. “My mom would be scared to death,” says Handlin. “But she could run a cell.”

At Vickers, the starting pay for robot operators is $16 per hour, as opposed to $9 per hour working a non-automated cell. In theory, the transition from laborer to operator offers employees a seamless path to financial security without leaving the factory floor.

***

FANUC’s American headquarters, an airy 375,000-square-foot complex set across 56 acres along the Clinton River in the Detroit suburb of Rochester Hills, is the center of the North American industrial automation universe. The facility is part warehouse, part showroom, and part training center. It’s also where engineers design and program new models before they are built—by other FANUC robots—in Japan.

All over the plant, robots give demonstrations of the things they can do. A delta robot, a newer model with a motor at the top and three legs that dangle down, briskly transfers a dozen Duracell batteries from one bin to another before doing a little victory dance to show off how far it can reach. Another robot lifts and rotates a 3,000-pound car.

While walking around the facility with Cicco, an enthusiastic electrical engineer in his late 30s who cracks a dimpled smile and never curses, the sheer quantity and range of FANUC’s robots begins to sink in. The M-1iA solders computer chips. The P-50iA paints radio knobs. The M-710iC reads barcodes.

According to Cicco, employee pushback has declined over the last 15 years as workers realized the rewards of becoming a programmer. But surrounded by mechanical box labelers, car door handle polishers, and cream cheese packagers, there’s a sense that programmers will soon be the only manufacturing jobs left. When that happens, American manufacturing may reign supreme. But will programming jobs keep pace with efficiency gains?

The question hangs in the air as the battery sorter continues its bizarre dance. It won’t be its last, but it’s hard to shake the feeling that, soon, it will no longer need a partner.

Illustrations by Sam Island

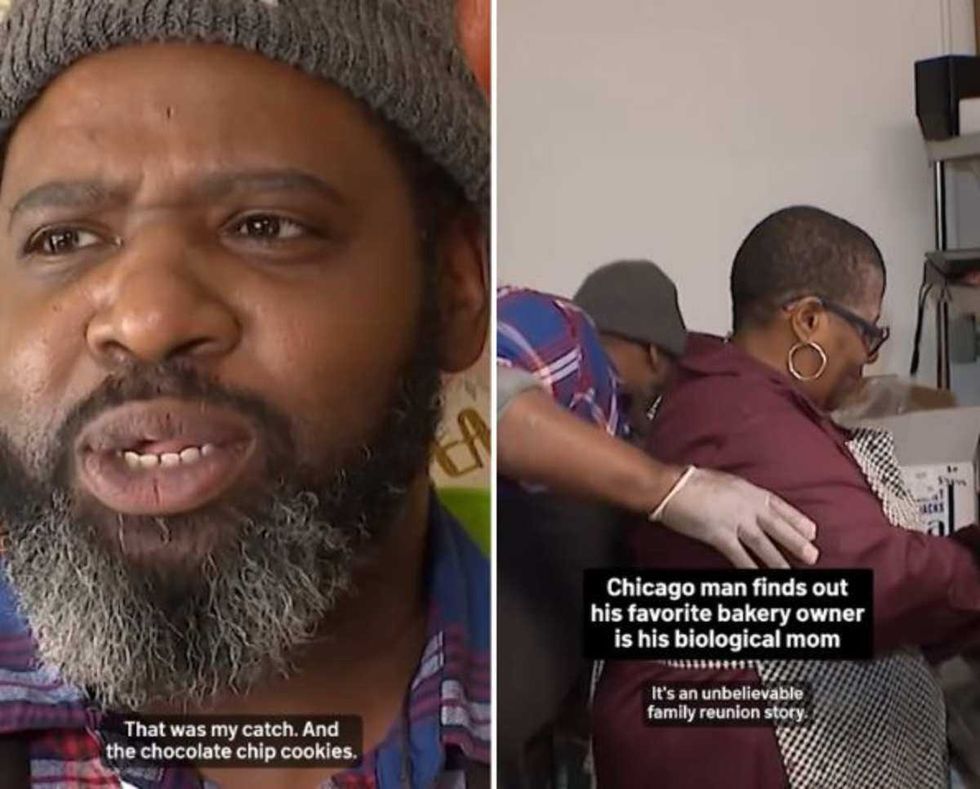

Screenshots of the man talking to the camera and with his momTikTok |

Screenshots of the man talking to the camera and with his momTikTok |  Screenshots of the bakery Image Source: TikTok |

Screenshots of the bakery Image Source: TikTok |

A woman hands out food to a homeless personCanva

A woman hands out food to a homeless personCanva A female artist in her studioCanva

A female artist in her studioCanva A woman smiling in front of her computerCanva

A woman smiling in front of her computerCanva  A woman holds a cup of coffee while looking outside her windowCanva

A woman holds a cup of coffee while looking outside her windowCanva  A woman flexes her bicepCanva

A woman flexes her bicepCanva  A woman cooking in her kitchenCanva

A woman cooking in her kitchenCanva  Two women console each otherCanva

Two women console each otherCanva  Two women talking to each otherCanva

Two women talking to each otherCanva  Two people having a lively conversationCanva

Two people having a lively conversationCanva  Two women embrace in a hugCanva

Two women embrace in a hugCanva

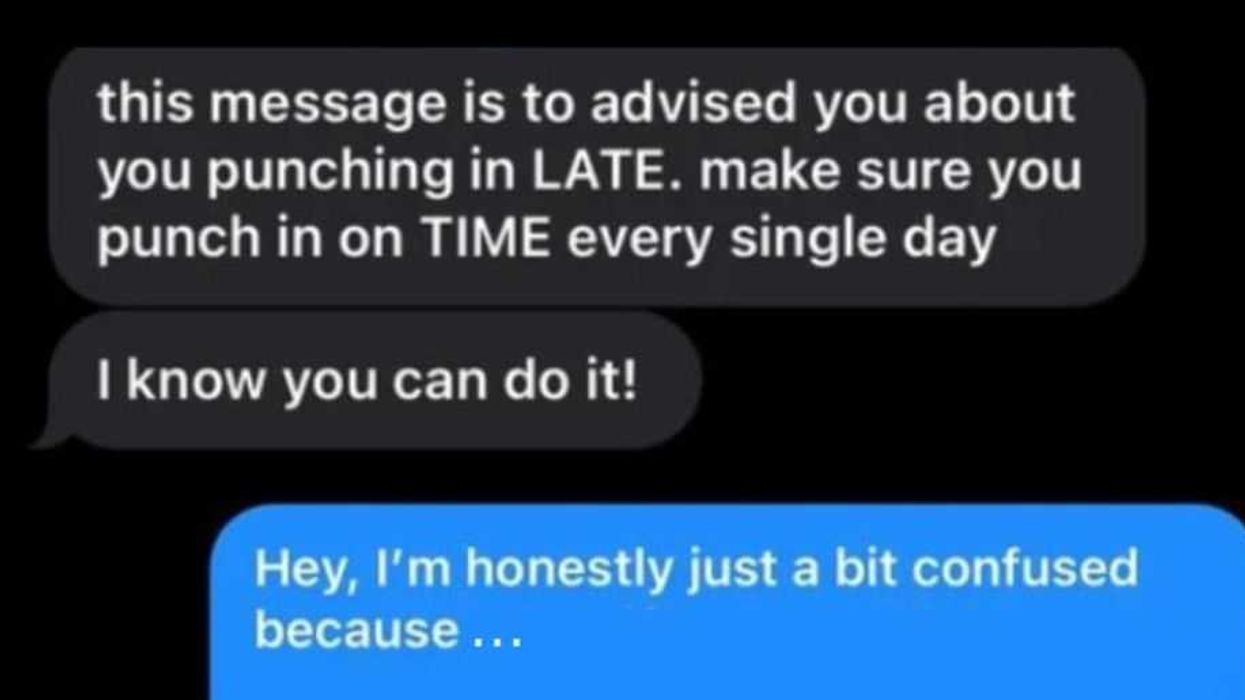

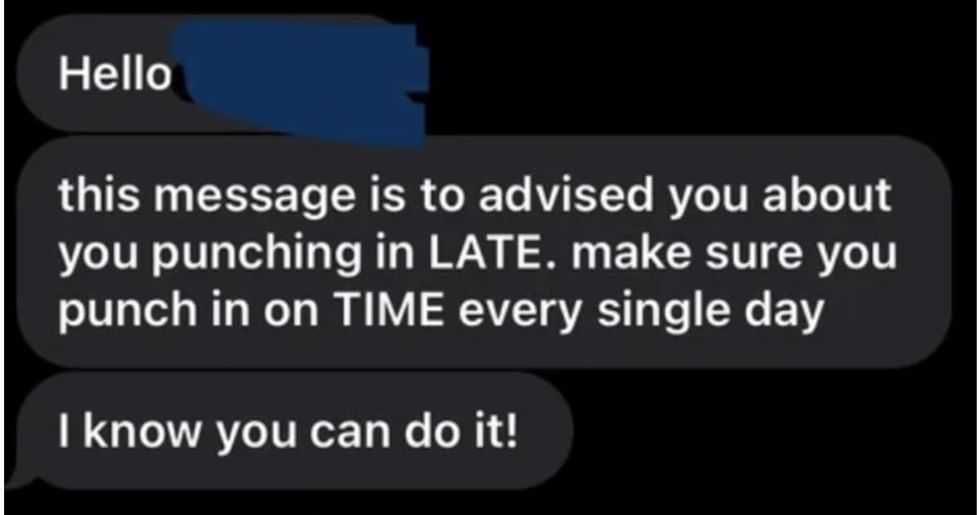

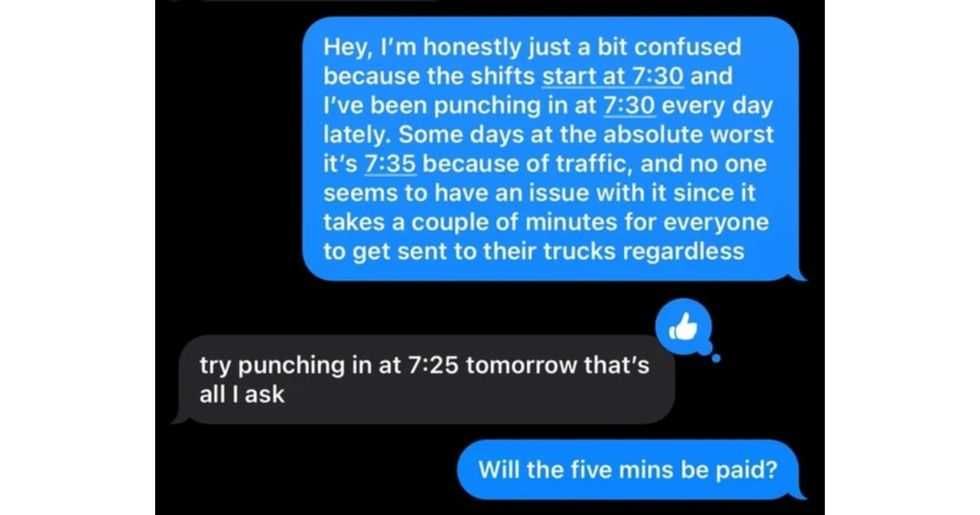

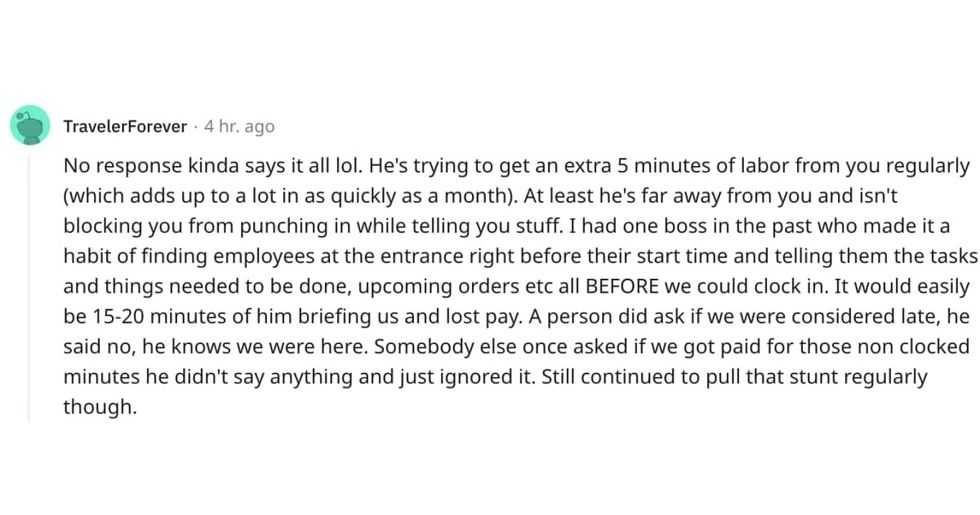

A reddit commentReddit |

A reddit commentReddit |  A Reddit commentReddit |

A Reddit commentReddit |  A Reddit commentReddit |

A Reddit commentReddit |  Stressed-out employee stares at their computerCanva

Stressed-out employee stares at their computerCanva

Who knows what adventures the bottle had before being discovered.

Who knows what adventures the bottle had before being discovered.

Gif of young girl looking at someone suspiciously via

Gif of young girl looking at someone suspiciously via

A bartender makes a drinkCanva

A bartender makes a drinkCanva